What is Honing?

Honing machines are metal abrading tools and the honing process utilizing hard tooling or honing stones and perishable abrasives stones for the correction of

- Diameter

- Shape

- Surface finish

- Positional tolerances of bores

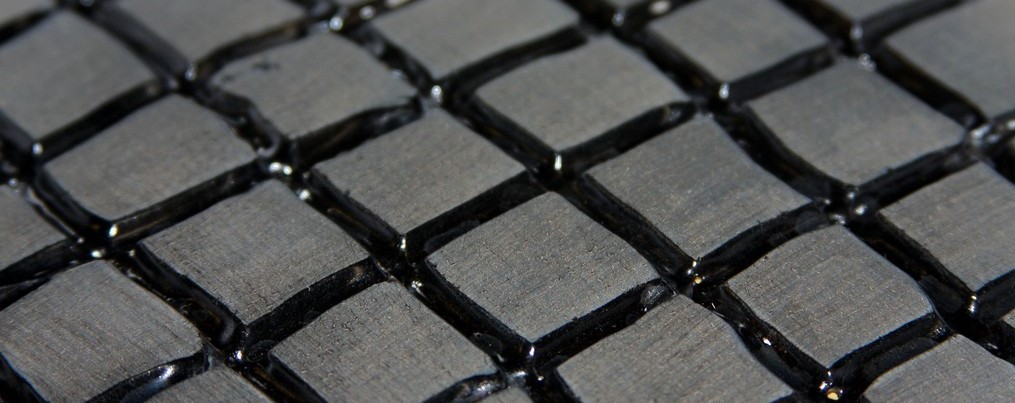

The honing process was developed to allow for perfection of bore geometry, size control, final surface finish and surface structuring. Lapmaster can help you learn the honing process that can provid the final sizing and creates the desired finish pattern on the interior of tubing or cylinder bores. Finishing is accomplished by expanding abrasive stones of suitable grit and grade against the work surface. The stones are rotated and reciprocated in the part with hone abrasive under controlled pressure. Combining rotation and reciprocation produces a cross-hatch pattern in the surface of the part being honed.

Why use a Lapmaster honing machine?

Lapmaster can provide a cost effective honing machining method for:

- Removing stock

- Generating exacting

- Bore tolerances

- Bore polishing

- Finishing bores of almost any material such a: sprayed coatings, CGI, Ceramics, etc.

Define The Honing Process:

The honing process provides the final sizing and creates the desired finish pattern on the interior of tubing or cylinder bores. Finishing is accomplished by expanding abrasive stones of suitable grit and grade against the work surface. The stones are rotated and reciprocated in the part with hone abrasive under controlled pressure. Combining rotation and reciprocation produces a cross-hatch pattern in the surface of the part being honed.

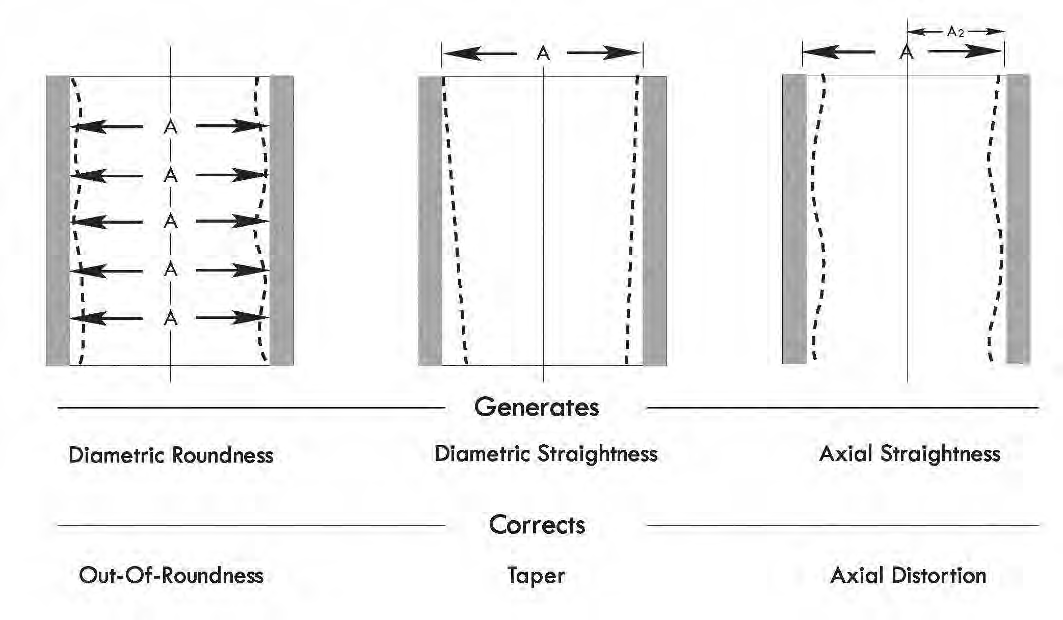

Lapmaster Honing Machines Perform Three Operations

First, it is a stock removal process (vertical honing machine) which takes out ruptured metal and reaches base metal.

Second, a finish pattern is generated to provide the best possible surface for promoting optimum lubricating conditions.

Third, honing stones assures extremely accurate straightness, roundness and size of the cylindrical surface.

What is single pass honing machine?

Single pass honing is done with a diamond abrasive, boring bar type honing tool. This type of honing tool produces a straight, round, and un-tapered bore in one pass of the tool through the part. Single pass honing is ideally suited for honing engine crank and cam bores. Since size is achieved in one pass, there is no crosshatch pattern in the finished part. The adjustable single pass tool expands the hone stones with a cone similar to standard tooling. However, the stones are not expanded and retracted as with conventional honing. The stones are only expanded to achieve size. The other difference is the hone tool is longer than standard tooling and the super abrasive coat the length of the tool. The single pass hone is tapered for about seven inches and has a final size section of 2.5 inches. See the photograph on the next page. The single pass tool has no in-process hone expansion, the machine must be stopped to adjust the tool.

When to Choose Lapmaster Single-Pass Honing Tooling?

Single-Pass honing machines, also called Bore Finishing, is selected for a variety of applications that have special needs involving honed cavities:

- Small diameter honing tool machine (normally within 2”)

- Honing tools for High-production quantities

- Proper honing tools can reduce the cost per part

- Reduced down-time for CNC honing tool change-over

- Repeatable accuracy for dimensional tolerances such as bore size, roundness, surface finish

- Only super-abrasive materials (Diamond and CBN) are used for the Single-Pass processing

- A high rate/volume of coolant is needed to constantly remove the chips from the honing area

- Oil or water-base coolants may be used for Single Pass honing, though oil is the most common

Single Pass honing process islimited to the types and volumes of material that can be removed. Specifically, the size and volume of chips removed must be no greater than there is clearance between the super-abrasive grits on the tool sleeve. As such, the Single Pass honing process is best suited for honing operations that produce a relatively small amount of chips, such as interrupted or short length bores. It is most successful (but not limited to) in honing cast iron and powdered metals.

Applications that feature a long length of material to be honed, small quantities and/or requiring a lot of material to be removed, are not the best suited parts for Single Pass honing. Rather, they may be best served using conventional Stroke Honing. In many cases, conventional Stroke Honing can also provide excellent dimensional geometry for these types of applications.

Why use Lapmaster Stroke Honing Machines / Systems?

Barnes Stroke Honing Machines & Finishing Systems offers a complete line of products for all honing requirements. We can offer fully integrated systems and machines for high volume production applications and equipment for low volume job shop applications. Lapmaster also offers used honing (rebuilt) and upgrade services for existing machines. We provide our customers with fully engineered complete custom solutions and offer a full line of accessories and consumables in addition to comprehensive training and repair services.

Our extensive line of Stroke honing machine / systems have the ability to hone machine bores with diameters ranging from 0.25 – 30 inches and bore lengths up to 75 feet. We offer systems for both medium to large-scale serial production as well as small batch production; these systems can be made to be manually operated or fully automated. With innovation and customer service as our main objectives, Barnes Stroke Honing & Finishing Systems is continuously researching and developing new technology and machinery. By consistently staying on top of the latest developments on the market, we ensure that our customers are provided with the most state-of-the-art production and control.

Why Single Pass Honing Machines / Systems?

Barnes Single Pass Honing/Finishing machine line is suitable for a variety of single pass honing applications. The flexible machine design can be configured with a single spindle for lower volume production requirements for the smallest of machine shops. It can also be arranged with multiple spindles to satisfy high volume production requirements for the most demanding of companies. Our Single Pass honing machines are designed and manufactured for minimal maintenance requirements and It's accessible configuration also reduces set-up and changeover time from part to part.

PRECISION SURFACING SOLUTIONS

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.

Visit SiteLapmaster Wolters

Founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials.

Visit SiteELB-Schliff

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".

Visit Siteaba Grinding

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.

Visit SiteREFORM

REFORM Grinding Technology GmbH is specialized in the sales, development & production of grinding machines for various applications at its location in Aschaffenburg (Germany).

Visit SiteKEHREN

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.

Visit SiteMicron

Produced in Germany since 2009, MICRON machines are compact and dynamically rigid grinding machines especially designed for Creep Feed and Profile grinding. MICRON is an industry leader in grinding of Hydraulic components like stators, rotors and van pumps.

Visit SitePeter Wolters

Founded in Germany in 1804 by Mr. Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936. In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and special materials of Meyer Burger. Further Information can be found at www.precision-surface.ch

Visit Site