What is pitch polishing?

Pitch polishing is a similar concept to the lapping process except it is using a pitch plate and much finer polishing media.

Lapmaster manufactures and uses single-sided polishing machines for a variety of optical components, i.e. optical flats, filters, prisms and for the refurbishing of customer’s optical components.

Typically, components range in size from 20mm diameter to 600mm diameter. Other sizes are achievable depending on both machine and component size and type.

Significant skill is required for pitch polishing, achieving tighter tolerances for surface flatness, roughness, parallelism and cosmetics than you would achieve using the conventional lapping process with coarser abrasives.

The pitch polishing process also produces a significantly improved surface quality with a typical Ra of less than 5 Å.

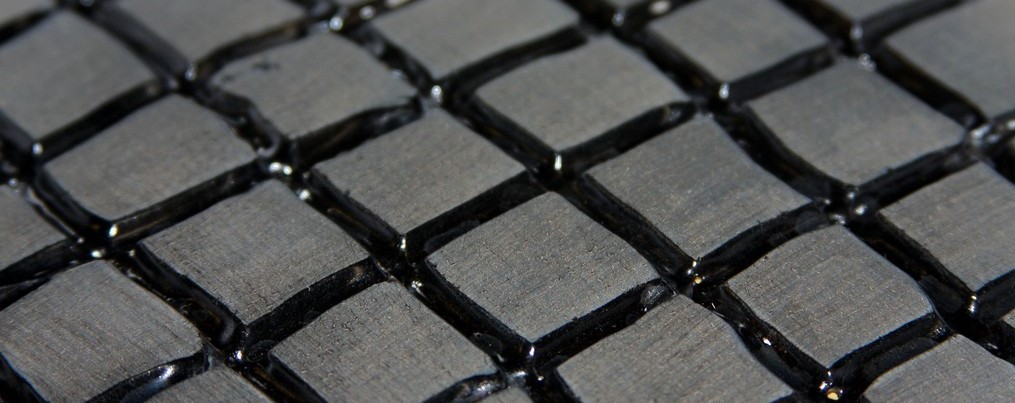

Pitch plates are a semi-fluid surface with a consistency similar to bitumen (asphalt) and are manufactured at our UK site. Concentric, spiral, radial and cross-hatched grooving is either hand cut or machine cut to allow the polishing slurry to flow beneath components, resulting in exceptional surface roughness and surface flatness.

The highly-experienced optical technicians at Lapmaster have extensive knowledge and experience of the optical polishing process and can provide consistent, high quality components.

Typical Optical Polishing Manufacturing Limits on our Lapmaster 48 Air Bearing Machine:

| Specifications | Measurements |

| Diameter | ≤ 300mm Optical Reference Flat |

| Flatness | ʎ/20 |

| Surface Roughness | ≥ 5 Å rms |

| Cosmetics (scratch/dig) | 60-40 to 10-5 |

What are lapmaster pitch polishing consumables?

Cerium Oxide

Cerium Oxide (CeO2) offers an enhanced polishing performance for optical flats, as well as other applications like filters and prisms. Cerium oxide has long lasting polishing efficiency providing excellent surface quality. Cerium oxide can retain its effectiveness over longer periods, even when used under demanding polishing conditions. It’s used for optical pitch applications and with a variety of pads. This abrasive is used strictly for polishing glass like materials on a soft polishing pad or pitch polishing plate. The average particle size utilized is typically somewhere in the range of one to three microns. Some brands of cerium oxide have a slightly high pH level. These abrasives cause an oxidation of the surface being polished. The oxidized material is mechanically removed by the rotating action of the pitch plate or polishing pad.

Polishing machines utilizing cerium oxide abrasive slurry should be protected from corrosion by using stainless steel components and epoxy paints. The water most commonly used with the cerium oxide is also a source of corrosion for unprotected ferrous metal machine components. The standard Lapmaster Wolters pitch polishing machines are constructed appropriately to eliminate corrosion problems from contact with water and high pH abrasive. It is important to consider this issue whenever quoting a standard lapping machine that is modified for cerium oxide polishing.

Why use Lapmaster Pitch Polishing Machines / Systems?

Lapmaster pitch polishing machines and systems offers a complete line of products for all pitch polishing requirements. We can offer fully integrated systems and machines for high volume pitch polishing and industrial production applications and equipment for low volume job shop applications. Lapmaster also offers used pitch polishing (rebuilt and refurbished) and upgrade services for existing polishing machines. We provide our pitch polishing customers with fully engineered complete custom solutions and offer a full line of accessories and consumables in addition to comprehensive training and repair services.

Our extensive line of pitch polishing machines / systems for both medium to large-scale serial production as well as small batch production; these systems can be made to be manually operated or fully automated. With innovation and customer service as our main objectives, Lapmaster continuously researching and developing new technology and pitch polishing machinery. By consistently staying on top of the latest developments on the market, we ensure that our customers are provided with the most state-of-the-art production and control.

PRECISION SURFACING SOLUTIONS

PRECISION SURFACING SOLUTIONS supports manufacturers in a wide variety of industries in which precision grinding, lapping, polishing, deburring and advanced materials processing equipment is commonly used. They all need high-quality, high-precision, stable and well-engineered machines to manufacture high-quality work pieces.

Visit SiteLapmaster Wolters

Founded in Chicago in 1948 as a manufacture of lapping and polishing machines for the mechanical seal market, Lapmaster has grown to a worldwide solution provider for more than 20 industries like precision optics and advanced materials.

Visit SiteELB-Schliff

ELB-Schliff Werkzeugmaschinen GmbH has been producing surface and profile grinding machines for over 70 years. The company was founded by Edmund Lang in the city of Babenhausen which led to the name "ELB-Schliff".

Visit Siteaba Grinding

The aba company was founded in 1898 under the name "Messwerkzeugfabrik Alig & Baumgärtel Aschaffenburg", hence the initials aba. Today, the aba Grinding Technologies is exclusively focused on the advancement and production of precision surface and profile grinding machines.

Visit SiteREFORM

REFORM Grinding Technology GmbH is specialized in the sales, development & production of grinding machines for various applications at its location in Aschaffenburg (Germany).

Visit SiteKEHREN

Founded in 1934, KEHREN is a well-established designer and builder of high-precision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface grinders with rotary tables and horizontal spindles, and surface grinders with dual rotary tables and vertical spindles.

Visit SiteMicron

Produced in Germany since 2009, MICRON machines are compact and dynamically rigid grinding machines especially designed for Creep Feed and Profile grinding. MICRON is an industry leader in grinding of Hydraulic components like stators, rotors and van pumps.

Visit SitePeter Wolters

Founded in Germany in 1804 by Mr. Peter Wolters, Peter Wolters has been producing lapping, polishing and fine grinding equipment since 1936. In 2019 Precision Surfacing Solutions acquired the division Wafer plant and service business for photovoltaic and special materials of Meyer Burger. Further Information can be found at www.precision-surface.ch

Visit Site