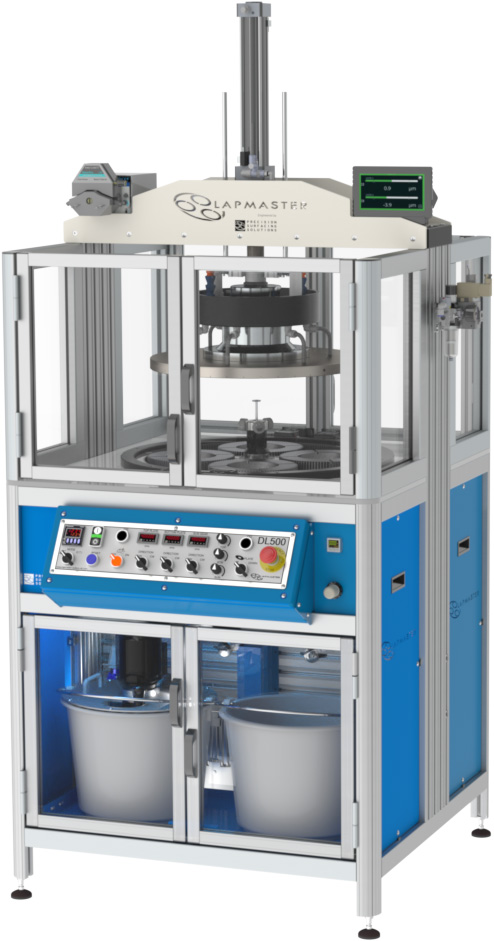

DL500

Double Face Lapping Machine

This Lapmaster series of Dual-Lap machines are based upon a two-way & three-way planetary concept designed to yield precise and repeatable results at an economical price. Excellent results have been obtained in the processing of a wide range of materials and components including glass, ceramics, crystals and ferrous materials.

- Ideally suited for small workshops and laboratories. 4 carriers, component thickness 0.5- 40 mm (0,0197- 1,57"), component diameter of max. 170 mm (6,69")

- Only the Inner and Outer Gears rotate allowing the carrier to move around the surface of the plates, whilst the top and bottom plate stay stationary.

Plate o.D. 19,6" / 500 mm

Brand: Lapmaster

Characteristics DL500 Lapping Machine

Basis

- Machine base made of extruded aluminum

- Independent drives with variable speed

- Operator control with 24VDC

- Interlocked safety guards

- Lapping agent distribution system with storage tank

- Lapping agent drain tank

STANDARD TOOL

- One set of cast iron overlap plates

- One set of cast iron conditioning gears

- One set of top disk weights

- One set of work supports

OPTIONAL TOOLS

- Stainless steel support discs for polishing

- Polishing pads

- Conditioning brushes

- OPTIONAL EQUIPMENT

- Electronic drive with variable speed

- DTI control

- Peristaltic pump

- Optional disks

- Table / trolley (DL175)

- Protective device

- Diamond spray unit

OPTIONAL EQUIPMENT

- Electronic drive with variable speed

- DTI control

- Peristaltic pump

- Optional disks

- Table / trolley (DL175)

- Protective device

- Diamond spray unit

We think ahead because full service starts with the product.

We ensure security. As a full-service provider, we offer everything you need to guarantee that your processes run like clockwork.

ConsumablesCustomized full-service offers for maximum production reliability.

Service