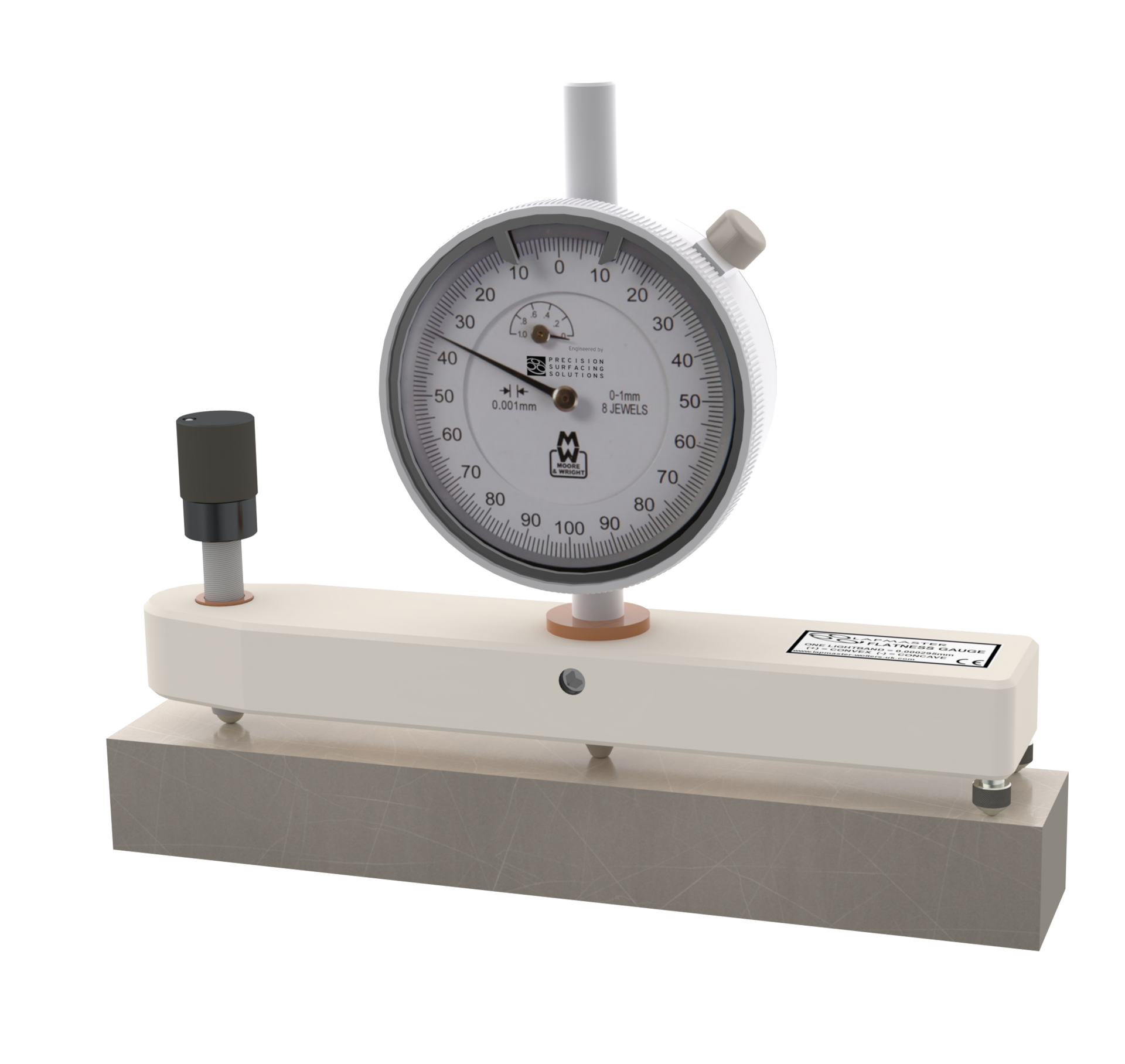

Flatness Gauges

Flatness Measuring Equipment

All Lapmaster precision flat lapping machines are of the conventional “ring lapping” type. This design permits high standards of flatness to be routinely achieved by careful adjustment of the lateral position of the conditioning rings on the annular lap plate track. The benefit of the Lapmaster flatness gauge is that it allows direct reading after it has been zeroed on the gauge block, which is used as a comparator reference gauge.

- Annual calibration service

- Special length flatness gauges available

Imperial dial gauges available

Technical Data:

Master gauge block lapped to a flatness of less than

< 1 µm (0.001 mm)

Brand Lapmaster

Characteristics Flatness Gauges .

- Calibrate the Flatness Gauge by placing it onto the Master Block and zeroing the indicator needle to “0’’. This is done by adjusting knurled Adjusting Screw over the single front foot.

- Carefully place the Flatness Gauge on the surface to be checked. Tilt the gauge to one side and slowly level to engage all feet onto the surface.

- Read and record the deviation from the master block displayed on the dial.

We think ahead because full service starts with the product.

We ensure security. As a full-service provider, we offer everything you need to guarantee that your processes run like clockwork.

ConsumablesCustomized full-service offers for maximum production reliability.

Service